INSTALLATION

General Information’s

Juteks vinyl floorings are designed only for interior applications.

To select the most appropriate item among Juteks range of products, you

should consider the traffic of the areas intended for installation. Softer

vinyl flooring is not suitable for areas under great loads, especially those

subjected to heavy traffic of casters and wheels (of office chairs, for

example).

Before installation always check products to ensure correct type, design

and colour. At the same time carefully inspect the material for any visible

damages and defects. Anyway that Juteks flooring are inspected before

leaving factory, it can happened that defects are not detected. In such

case, contact Juteks distributor for assistance.

NOTE:

Juteks will not pay labour charges on claims filed for materials

installed with obvious visible defects.

Storage and Handling

Juteks products must be stored in interior locations, protected from the

weather. Storage area must be dry and without direct sunlight. Because

vinyl flooring can become yellow, if it is exposed to exhaust from gas and

oil combustion, be sure that storage area will be free of such combustion

(outside and inside).

Storage temperatures must be between 0°C and 30°C.

Flooring products can be damaged by rough handling, that’s why handle

products with care.

If material is pre-cut and then stored for some time, it must be rolled around

cardboard tube before installation.

Installation

Subfloor, Juteks flooring and adhesive must be kept for conditioning,

24 - 48 hours prior to, during and after the installation in a room, with a

temperature between 18 - 29°C and a relative humidity of 50-60%.

Before installation material must be rolled face out until ready to begin

installation. However it can be pre-cut (accurately) for fitting the room, but

after that be sure to roll face out again (do not roll the material face in, until

taking it into the room for installation). When material is rolled face out, be

careful to not damage surface while handling such roll.

CAUTION:

If pre-cut roll is stored for some time before installation, please

follow Juteks instruction on

(Storage and Handling section).

Avoid creasing or folding of material, because it could lead to permanent

crease and damage in the flooring surface. Do not write on the backing

with an ink pen, felt tipped marker, …; if necessary use a graphite pencil

only.

Be sure to fit the flooring correctly and completely to the room. By fitting,

leave along walls (furniture …) approx. 2-3 mm interspace for distension.

When installing material in room, be sure that all sheets are installed in

printing direction (in direction in which rolls are unrolled).

If more than one roll of same colour is installed, all rolls must be from the

same production series (same batch number). Juteks cannot guarantee

colour repeat between different production series.

It is necessary to plan the direction of fitting the roll in order to avoid (if possible)

seams in the doorway, along the main walking areas, between outlets, etc. In

square rooms, it is best to lay the rolls parallel to the entrance light, while in

long and narrow rooms it is better to have them installed lengthwise.

CAUTION:

To ensure to have rolls from one batch, please carefully follow

instructions on

(Roll labelling information).

For gluing vinyl flooring onto the subfloor, use a suitable dispersive

adhesive (follow the adhesive manufacturer’s instructions for use). Usually

for applying of adhesive notched trowel is used, that’s why always check

adhesive label for the proper notching, because too much adhesive can

lead to indentations. Juteks recommends applying adhesive over the entire

surface. For more information’s about gluing and further installation please

follow instructions on

Floor heating system

Prior to the installation of vinyl sheet flooring, it is important to ascertain

and enable a correct and optimal operation of any floor heating systems.

Floor heating must be switched off for 48 hours before and 48 hours after

the installation of vinyl flooring. During this time, it is necessary to provide

alternative heating in order to ensure a temperature between 18°C and

29°C. After that, the temperature should be raised gradually, a few degrees

per day, until it reaches the preferred level. The temperature at the subfloor

level should never exceed 27°C.

The thermal resistance of vinyl flooring affects the temperature level of the

heating medium. To ensure a sufficient transmission of warmth, you should

select flooring with a thermal resistance below 0,10 m

2

K/W. Otherwise you

would have to set the temperature of the heating medium too high to

achieve the appropriate transmission of heat.

NOTE:

Thermal resistance of Juteks flooring varies from 0,01 m

2

K/W and up

to 0,04 m

2

K/W.

Hot welding

With hot welding, a vinyl rod (same type of material as the covering)

and the floor covering material at the seam are heated to a sufficient

temperature whereby they are fused together.. It ensures a permanent

seal and a longer life for the floorcovering. Most specifications make

hot welding mandatory, since it prevents ingress of dirt and bacteria into

seams and provides a floor surface which is impermeable to water. It is

also recommended for areas with floor heating systems. However,welding

will only aid maintenance of high standards of hygiene if it is executed

correctly and should only be done by a trained professional.

The procedure of hot welding

Install the floor covering as described in the Juteks installation method.

Allow the adhesive to dry for a minimum of 48 hours before hot-welding

the seams.

When the adhesive has fully cured , cut a groove along the seam using

a standard grooving tool ( »U« shaped cutter). The depth of the groove

depends on the thickness and type of covering to be welded and the

diameter of weld rod to be used, but should not extending more than two-

thirds into the wearlayer thickness.

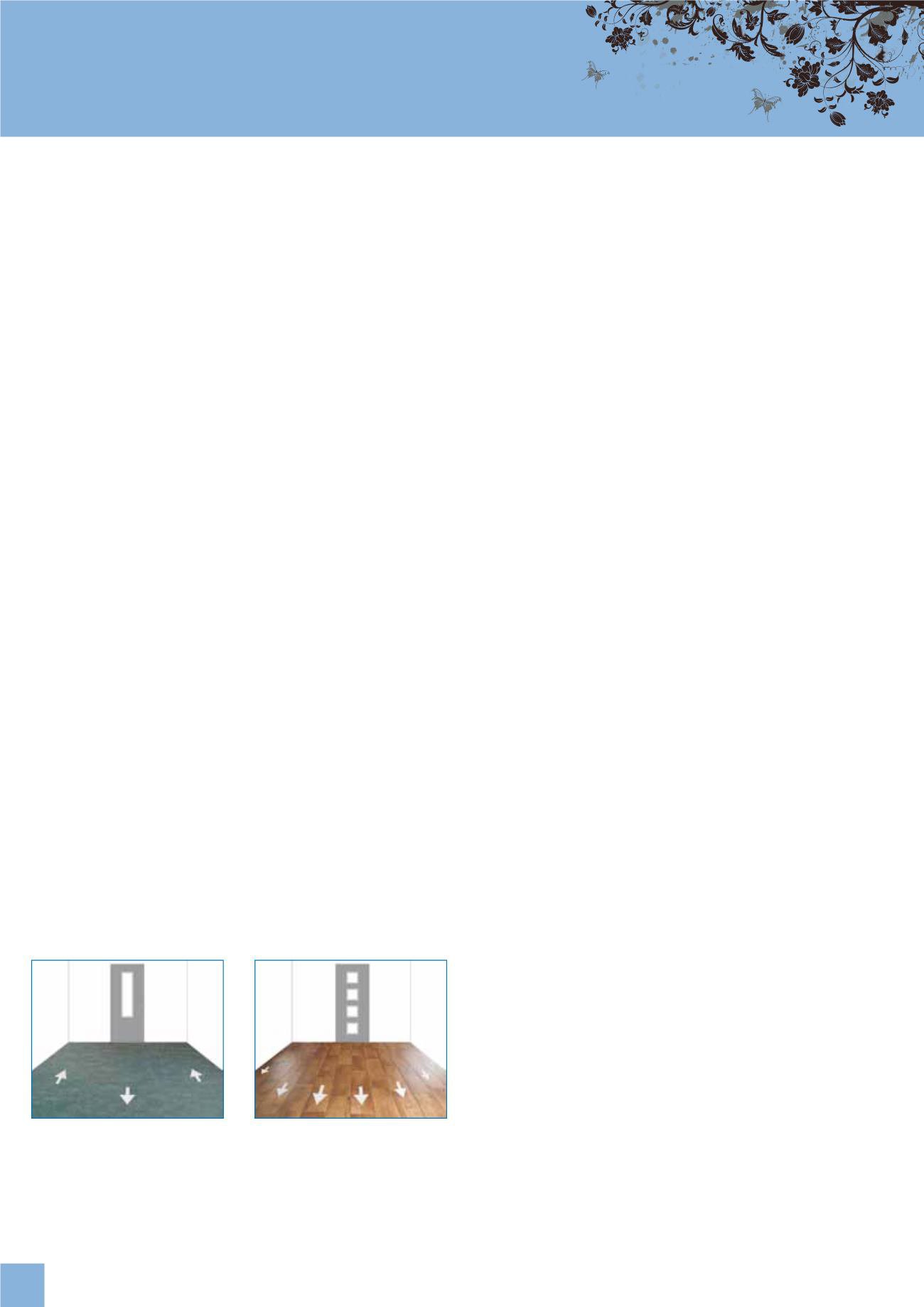

All over designs sheets, must be

installed in opposite direction.

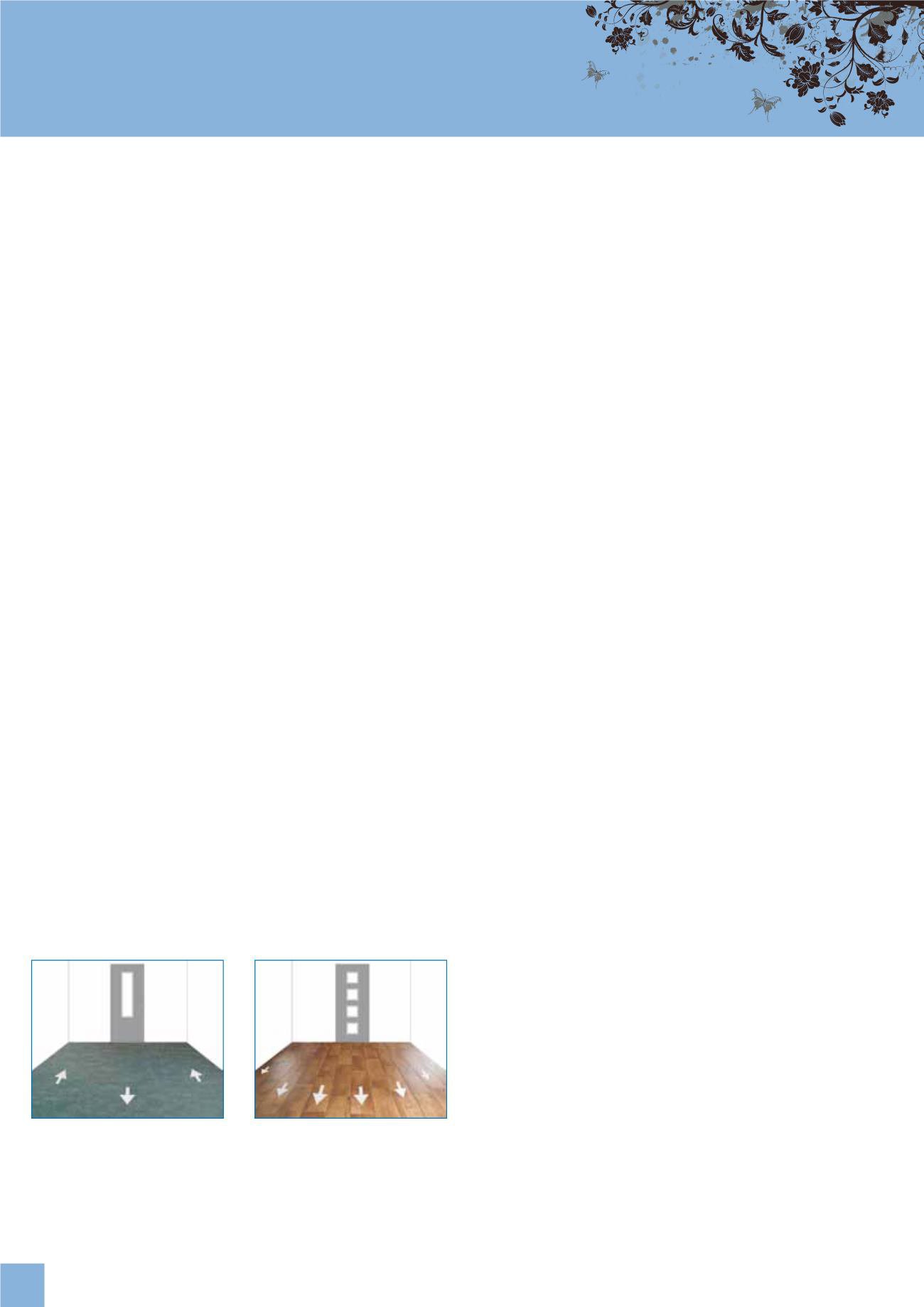

All other designs (like wood, tiles, …)

sheets, must be installed in same

direction.

installation and

maintenance

44